|

|

| 第35行: |

第35行: |

| | [[文件:02S11303.png|480px|缩略图|居中]] | | [[文件:02S11303.png|480px|缩略图|居中]] |

| | * 例子程序: | | * 例子程序: |

| − | <pre style='color:blue'>#include "Wire.h" | + | <pre style='color:blue'> |

| − | // I2Cdev and MPU9250 must be installed as libraries, or else the .cpp/.h files

| + | #include "quaternionFilters.h" |

| − | // for both classes must be in the include path of your project

| + | |

| − | #include "I2Cdev.h" | + | |

| | #include "MPU9250.h" | | #include "MPU9250.h" |

| | | | |

| − | // class default I2C address is 0x68 | + | #define I2Cclock 400000 |

| − | // specific I2C addresses may be passed as a parameter here | + | #define I2Cport Wire |

| − | // AD0 low = 0x68 (default for InvenSense evaluation board)

| + | #define MPU9250_ADDRESS MPU9250_ADDRESS_AD0 // Use either this line or the next to select which I2C address your device is using |

| − | // AD0 high = 0x69

| + | //#define MPU9250_ADDRESS MPU9250_ADDRESS_AD1 |

| − | MPU9250 accelgyro;

| + | |

| − | I2Cdev I2C_M;

| + | |

| | | | |

| − | uint8_t buffer_m[6];

| + | MPU9250 myIMU0(MPU9250_ADDRESS_AD0, I2Cport, I2Cclock); |

| − | | + | MPU9250 myIMU1(MPU9250_ADDRESS_AD1, I2Cport, I2Cclock); |

| − | int16_t ax, ay, az;

| + | |

| − | int16_t gx, gy, gz;

| + | |

| − | int16_t mx, my, mz;

| + | |

| − | | + | |

| − | | + | |

| − | | + | |

| − | float heading;

| + | |

| − | float tiltheading;

| + | |

| − | | + | |

| − | float Axyz[3];

| + | |

| − | float Gxyz[3];

| + | |

| − | float Mxyz[3];

| + | |

| − | | + | |

| − | | + | |

| − | #define sample_num_mdate 5000

| + | |

| − | | + | |

| − | volatile float mx_sample[3];

| + | |

| − | volatile float my_sample[3];

| + | |

| − | volatile float mz_sample[3];

| + | |

| − | | + | |

| − | static float mx_centre = 0;

| + | |

| − | static float my_centre = 0;

| + | |

| − | static float mz_centre = 0;

| + | |

| − | | + | |

| − | volatile int mx_max =0;

| + | |

| − | volatile int my_max =0;

| + | |

| − | volatile int mz_max =0;

| + | |

| − | | + | |

| − | volatile int mx_min =0;

| + | |

| − | volatile int my_min =0;

| + | |

| − | volatile int mz_min =0;

| + | |

| | | | |

| | + | byte c = 0x00; |

| | + | byte d = 0x00; |

| | + | bool ledOn = true; |

| | | | |

| | void setup() { | | void setup() { |

| − | // join I2C bus (I2Cdev library doesn't do this automatically) | + | // put your setup code here, to run once: |

| − | Wire.begin();

| + | |

| − | | + | |

| − | // initialize serial communication

| + | |

| − | // (38400 chosen because it works as well at 8MHz as it does at 16MHz, but

| + | |

| − | // it's really up to you depending on your project)

| + | |

| | Serial.begin(38400); | | Serial.begin(38400); |

| | + | while(!Serial){}; |

| | | | |

| − | // initialize device | + | pinMode(13, OUTPUT); |

| − | Serial.println("Initializing I2C devices...");

| + | |

| − | accelgyro.initialize();

| + | |

| − | | + | |

| − | // verify connection

| + | |

| − | Serial.println("Testing device connections...");

| + | |

| − | Serial.println(accelgyro.testConnection() ? "MPU9250 connection successful" : "MPU9250 connection failed");

| + | |

| − |

| + | |

| − | delay(1000);

| + | |

| − | Serial.println(" ");

| + | |

| − |

| + | |

| − | //Mxyz_init_calibrated ();

| + | |

| | | | |

| | } | | } |

| | | | |

| − | void loop() | + | void loop() { |

| − | {

| + | // put your main code here, to run repeatedly: |

| − |

| + | |

| − | getAccel_Data();

| + | |

| − | getGyro_Data();

| + | |

| − | getCompassDate_calibrated(); // compass data has been calibrated here

| + | |

| − | getHeading(); //before we use this function we should run 'getCompassDate_calibrated()' frist, so that we can get calibrated data ,then we can get correct angle .

| + | |

| − | getTiltHeading();

| + | |

| − |

| + | |

| − | Serial.println("calibration parameter: ");

| + | |

| − | Serial.print(mx_centre);

| + | |

| − | Serial.print(" ");

| + | |

| − | Serial.print(my_centre);

| + | |

| − | Serial.print(" ");

| + | |

| − | Serial.println(mz_centre);

| + | |

| − | Serial.println(" ");

| + | |

| − |

| + | |

| − |

| + | |

| − | Serial.println("Acceleration(g) of X,Y,Z:");

| + | |

| − | Serial.print(Axyz[0]);

| + | |

| − | Serial.print(",");

| + | |

| − | Serial.print(Axyz[1]);

| + | |

| − | Serial.print(",");

| + | |

| − | Serial.println(Axyz[2]);

| + | |

| − | Serial.println("Gyro(degress/s) of X,Y,Z:");

| + | |

| − | Serial.print(Gxyz[0]);

| + | |

| − | Serial.print(",");

| + | |

| − | Serial.print(Gxyz[1]);

| + | |

| − | Serial.print(",");

| + | |

| − | Serial.println(Gxyz[2]);

| + | |

| − | Serial.println("Compass Value of X,Y,Z:");

| + | |

| − | Serial.print(Mxyz[0]);

| + | |

| − | Serial.print(",");

| + | |

| − | Serial.print(Mxyz[1]);

| + | |

| − | Serial.print(",");

| + | |

| − | Serial.println(Mxyz[2]);

| + | |

| − | Serial.println("The clockwise angle between the magnetic north and X-Axis:");

| + | |

| − | Serial.print(heading);

| + | |

| − | Serial.println(" ");

| + | |

| − | Serial.println("The clockwise angle between the magnetic north and the projection of the positive X-Axis in the horizontal plane:");

| + | |

| − | Serial.println(tiltheading);

| + | |

| − | Serial.println(" ");

| + | |

| − | Serial.println(" ");

| + | |

| − | Serial.println(" ");

| + | |

| | | | |

| | + | c = myIMU0.readByte(MPU9250_ADDRESS_AD0, WHO_AM_I_MPU9250); |

| | + | d = myIMU1.readByte(MPU9250_ADDRESS_AD1, WHO_AM_I_MPU9250); |

| | | | |

| | + | Serial.print("Received AD0: 0x"); |

| | + | Serial.print(c, HEX); |

| | + | Serial.print(", AD1: 0x"); |

| | + | Serial.println(d, HEX); |

| | + | digitalWrite(13, ledOn); |

| | + | ledOn = !ledOn; |

| | + | delay(100); |

| | | | |

| − | delay(300);

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| | } | | } |

| − | | + | </pre> |

| − | | + | |

| − | void getHeading(void)

| + | |

| − | {

| + | |

| − | heading=180*atan2(Mxyz[1],Mxyz[0])/PI;

| + | |

| − | if(heading <0) heading +=360;

| + | |

| − | }

| + | |

| − | | + | |

| − | void getTiltHeading(void)

| + | |

| − | {

| + | |

| − | float pitch = asin(-Axyz[0]);

| + | |

| − | float roll = asin(Axyz[1]/cos(pitch));

| + | |

| − | | + | |

| − | float xh = Mxyz[0] * cos(pitch) + Mxyz[2] * sin(pitch);

| + | |

| − | float yh = Mxyz[0] * sin(roll) * sin(pitch) + Mxyz[1] * cos(roll) - Mxyz[2] * sin(roll) * cos(pitch);

| + | |

| − | float zh = -Mxyz[0] * cos(roll) * sin(pitch) + Mxyz[1] * sin(roll) + Mxyz[2] * cos(roll) * cos(pitch);

| + | |

| − | tiltheading = 180 * atan2(yh, xh)/PI;

| + | |

| − | if(yh<0) tiltheading +=360;

| + | |

| − | }

| + | |

| − | | + | |

| − | | + | |

| − | | + | |

| − | void Mxyz_init_calibrated ()

| + | |

| − | {

| + | |

| − |

| + | |

| − | Serial.println(F("Before using 9DOF,we need to calibrate the compass frist,It will takes about 2 minutes."));

| + | |

| − | Serial.print(" ");

| + | |

| − | Serial.println(F("During calibratting ,you should rotate and turn the 9DOF all the time within 2 minutes."));

| + | |

| − | Serial.print(" ");

| + | |

| − | Serial.println(F("If you are ready ,please sent a command data 'ready' to start sample and calibrate."));

| + | |

| − | while(!Serial.find("ready"));

| + | |

| − | Serial.println(" ");

| + | |

| − | Serial.println("ready");

| + | |

| − | Serial.println("Sample starting......");

| + | |

| − | Serial.println("waiting ......");

| + | |

| − |

| + | |

| − | get_calibration_Data ();

| + | |

| − |

| + | |

| − | Serial.println(" ");

| + | |

| − | Serial.println("compass calibration parameter ");

| + | |

| − | Serial.print(mx_centre);

| + | |

| − | Serial.print(" ");

| + | |

| − | Serial.print(my_centre);

| + | |

| − | Serial.print(" ");

| + | |

| − | Serial.println(mz_centre);

| + | |

| − | Serial.println(" ");

| + | |

| − | }

| + | |

| − | | + | |

| − | | + | |

| − | void get_calibration_Data ()

| + | |

| − | {

| + | |

| − | for (int i=0; i<sample_num_mdate;i++)

| + | |

| − | {

| + | |

| − | get_one_sample_date_mxyz();

| + | |

| − | /*

| + | |

| − | Serial.print(mx_sample[2]);

| + | |

| − | Serial.print(" ");

| + | |

| − | Serial.print(my_sample[2]); //you can see the sample data here .

| + | |

| − | Serial.print(" ");

| + | |

| − | Serial.println(mz_sample[2]);

| + | |

| − | */

| + | |

| − | | + | |

| − | | + | |

| − |

| + | |

| − | if (mx_sample[2]>=mx_sample[1])mx_sample[1] = mx_sample[2];

| + | |

| − | if (my_sample[2]>=my_sample[1])my_sample[1] = my_sample[2]; //find max value

| + | |

| − | if (mz_sample[2]>=mz_sample[1])mz_sample[1] = mz_sample[2];

| + | |

| − |

| + | |

| − | if (mx_sample[2]<=mx_sample[0])mx_sample[0] = mx_sample[2];

| + | |

| − | if (my_sample[2]<=my_sample[0])my_sample[0] = my_sample[2];//find min value

| + | |

| − | if (mz_sample[2]<=mz_sample[0])mz_sample[0] = mz_sample[2];

| + | |

| − |

| + | |

| − | }

| + | |

| − |

| + | |

| − | mx_max = mx_sample[1];

| + | |

| − | my_max = my_sample[1];

| + | |

| − | mz_max = mz_sample[1];

| + | |

| − |

| + | |

| − | mx_min = mx_sample[0];

| + | |

| − | my_min = my_sample[0];

| + | |

| − | mz_min = mz_sample[0];

| + | |

| − |

| + | |

| − | | + | |

| − |

| + | |

| − | mx_centre = (mx_max + mx_min)/2;

| + | |

| − | my_centre = (my_max + my_min)/2;

| + | |

| − | mz_centre = (mz_max + mz_min)/2;

| + | |

| − |

| + | |

| − | }

| + | |

| − | | + | |

| − | | + | |

| − | | + | |

| − | | + | |

| − | | + | |

| − | | + | |

| − | void get_one_sample_date_mxyz()

| + | |

| − | {

| + | |

| − | getCompass_Data();

| + | |

| − | mx_sample[2] = Mxyz[0];

| + | |

| − | my_sample[2] = Mxyz[1];

| + | |

| − | mz_sample[2] = Mxyz[2];

| + | |

| − | }

| + | |

| − | | + | |

| − | | + | |

| − | void getAccel_Data(void)

| + | |

| − | {

| + | |

| − | accelgyro.getMotion9(&ax, &ay, &az, &gx, &gy, &gz, &mx, &my, &mz);

| + | |

| − | Axyz[0] = (double) ax / 16384;//16384 LSB/g

| + | |

| − | Axyz[1] = (double) ay / 16384;

| + | |

| − | Axyz[2] = (double) az / 16384;

| + | |

| − | }

| + | |

| − | | + | |

| − | void getGyro_Data(void)

| + | |

| − | {

| + | |

| − | accelgyro.getMotion9(&ax, &ay, &az, &gx, &gy, &gz, &mx, &my, &mz);

| + | |

| − | Gxyz[0] = (double) gx * 250 / 32768;

| + | |

| − | Gxyz[1] = (double) gy * 250 / 32768;

| + | |

| − | Gxyz[2] = (double) gz * 250 / 32768;

| + | |

| − | }

| + | |

| − | | + | |

| − | void getCompass_Data(void)

| + | |

| − | {

| + | |

| − | I2C_M.writeByte(MPU9150_RA_MAG_ADDRESS, 0x0A, 0x01); //enable the magnetometer

| + | |

| − | delay(10);

| + | |

| − | I2C_M.readBytes(MPU9150_RA_MAG_ADDRESS, MPU9150_RA_MAG_XOUT_L, 6, buffer_m);

| + | |

| − |

| + | |

| − | mx = ((int16_t)(buffer_m[1]) << 8) | buffer_m[0] ;

| + | |

| − | my = ((int16_t)(buffer_m[3]) << 8) | buffer_m[2] ;

| + | |

| − | mz = ((int16_t)(buffer_m[5]) << 8) | buffer_m[4] ;

| + | |

| − |

| + | |

| − | //Mxyz[0] = (double) mx * 1200 / 4096;

| + | |

| − | //Mxyz[1] = (double) my * 1200 / 4096;

| + | |

| − | //Mxyz[2] = (double) mz * 1200 / 4096;

| + | |

| − | Mxyz[0] = (double) mx * 4800 / 8192;

| + | |

| − | Mxyz[1] = (double) my * 4800 / 8192;

| + | |

| − | Mxyz[2] = (double) mz * 4800 / 8192;

| + | |

| − | }

| + | |

| − | | + | |

| − | void getCompassDate_calibrated ()

| + | |

| − | {

| + | |

| − | getCompass_Data();

| + | |

| − | Mxyz[0] = Mxyz[0] - mx_centre;

| + | |

| − | Mxyz[1] = Mxyz[1] - my_centre;

| + | |

| − | Mxyz[2] = Mxyz[2] - mz_centre;

| + | |

| − | }</pre>

| + | |

| | | | |

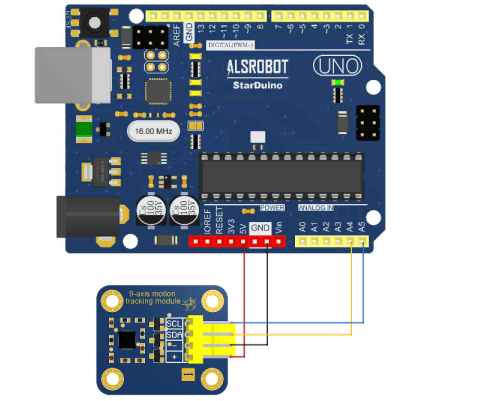

| | * 程序效果 | | * 程序效果 |

| − | 将程序下载后,将九轴姿态检测传感器水平静止放置,打开串口监视器,波特率调整为38400,等待显示“Initializing I2C devices... Testing device connections... MPU9250 connection successful”后晃动传感器,观察数据变化。

| + | 将程序下载后,将九轴姿态检测传感器水平静止放置,打开串口监视器,波特率调整为38400,晃动传感器,观察数据变化。 |

| − | [[文件:02S11304.png|530px|缩略图|居中]]

| + | |

| | | | |

| | ==相关推荐== | | ==相关推荐== |

九轴姿态检测传感器基于MPU-9150开发而成,MPU-9150是世界上第一款集成了三轴陀螺仪、三轴加速度计及三轴磁力计的芯片。MPU-9150主要应用于低功耗、低价格和高性能消费电子产品,包含智能手机、平板电脑和可穿戴设备中。MPU-9150包含三个16位ADC用于陀螺仪信号进行数字化输出、三个16位ADC用于加速度计信号数字化输出及三个13位ADC用于磁力计信号数字化输出。九轴姿态检测传感器可广泛应用于航模无人机,机器人,天线云台,聚光太阳能,地面及水下设备,虚拟现实,人体运动分析等需要低成本、高动态三维姿态测量的产品设备中。